-

Phone:

Phone: -

Email:

Email:

Affordable Baling Wire Options for Your Farming and Packaging Needs

The Versatility and Utility of Baling Wire An Essential Tool for Various Industries

Baling wire is a crucial component in numerous industries, primarily used for binding and compressing materials into bales. Its applications span from agriculture to recycling, making it an essential tool that enhances efficiency and productivity. This article explores the various types of baling wire available for sale, their benefits, and the industries that rely on this versatile product.

Types of Baling Wire

Baling wire comes in various materials and sizes, each serving different purposes. The most common types of baling wire are

1. Steel Baling Wire This is the most widely used type due to its strength and durability. Steel baling wire can withstand substantial tension and is typically used in heavy-duty applications, such as binding cardboard, scrap metal, and other materials.

2. Polyester Baling Wire Lightweight and resistant to corrosion, polyester baling wire is ideal for industries that require a less robust option. It is commonly used in agriculture for bundling hay and straw as it does not rust and is less likely to damage crops.

3. Aluminum Baling Wire Known for its lightweight characteristics, aluminum baling wire is often used in the recycling industry. It is resistant to environmental factors, making it suitable for outdoor applications.

4. Twisted Wire This type of wire is often used in applications requiring flexibility and strength. It is twisted to maximize tensile strength and is typically utilized for binding products such as cardboard and paper.

5. Barbed Wire Used primarily in agricultural fencing, barbed wire provides protection against trespassing animals. Its sharp barbs discourage livestock and wild animals from crossing boundaries.

Benefits of Baling Wire

Baling wire offers numerous advantages that contribute to its popularity across various sectors

baling wire for sale

2. Cost-Effectiveness Purchase of baling wire represents a significant investment in terms of operational efficiency. Its ability to securely bind materials reduces waste and enhances storage capabilities, leading to savings in transportation and storage costs.

3. Ease of Use Most baling wires can be easily handled and applied, making them accessible to workers across different industries. The lightweight nature of certain types also means that workers can use them without excessive strain.

4. Versatility Baling wire is not limited to one industry; it is used in agriculture for bailing hay, in recycling plants for bundling materials, and even in construction for securing various components.

5. Environmental Impact Using baling wire promotes recycling practices by ensuring materials can be more easily collected and transported to recycling facilities, thus supporting sustainability efforts.

Industries That Use Baling Wire

Several industries rely heavily on baling wire

1. Agriculture Farmers use baling wire to bundle hay and other forage materials, ensuring that they can be stored efficiently and transported easily.

2. Recycling In recycling plants, baling wire is crucial for compacting paper, plastics, and metals into manageable bales, which optimizes storage and transport.

3. Manufacturing and Warehousing These sectors use baling wire to keep loose materials organized and secured, enhancing safety and efficiency on production lines.

4. Construction Baling wire is sometimes used to hold building materials together or for temporary support structures.

In conclusion, baling wire may seem like a simple tool, but its versatility and reliability make it a fundamental component across multiple industries. Whether you are in agriculture, recycling, manufacturing, or construction, investing in quality baling wire can lead to improved efficiency, safety, and cost savings. With various options available for sale, businesses can choose the best type that meets their specific needs, ensuring they are equipped to handle the demands of their respective industries effectively.

-

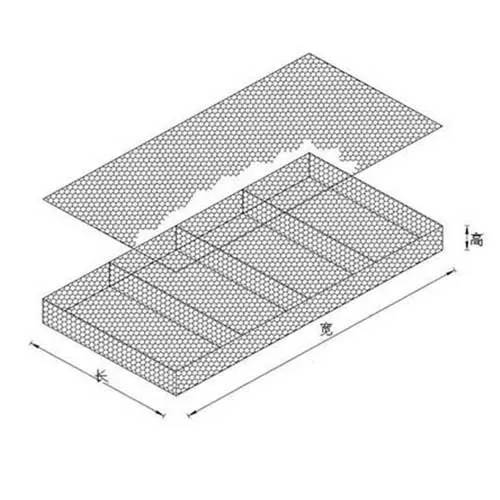

Reinforce Your Projects with Versatile Hexagonal Wire MeshNewsSep.12,2024

-

PVC WireNewsSep.12,2024

-

Maximize Your Closet Space with Clothes Hanger WireNewsSep.12,2024

-

Enhance Safety and Stability with Premium Rock Netting SolutionsNewsSep.12,2024

-

Bucket Handle WireNewsSep.12,2024

-

Baling Wire: Your Ultimate Solution for Securing and BundlingNewsSep.12,2024

-

What’s the Cost of Securing Your Property? Breaking Down Barbed Wire Fence PricesNewsAug.30,2024