-

Phone:

Phone: -

Email:

Email:

Understanding Baling Wire Gauge for Efficient Use in Packaging and Agriculture

Understanding Baling Wire Gauge A Comprehensive Guide

Baling wire is an essential component in various industries, especially in recycling, agriculture, and manufacturing. It is primarily used to bundle materials tightly for shipping, storage, or recycling processes. One critical aspect that professionals and hobbyists alike must understand when working with baling wire is its gauge. The term gauge refers to the thickness of the wire, which plays a vital role in determining its strength, flexibility, and suitability for specific applications.

What is Wire Gauge?

Wire gauge is a standardized system used to specify the diameter of the wire. The system commonly used in the United States is the American Wire Gauge (AWG) system. In this system, the gauge number inversely correlates with the diameter of the wire—the larger the gauge number, the thinner the wire. For example, a 10-gauge wire is thicker than a 20-gauge wire. Understanding this relationship is crucial when selecting baling wire for your specific needs.

Importance of Choosing the Right Gauge

Choosing the appropriate wire gauge for baling is vital for several reasons

1. Strength A thicker wire (lower gauge number) will generally have a higher tensile strength, making it more suitable for holding heavier loads. On the other hand, a thinner wire may not support the weight, leading to breakage and operational inefficiencies.

2. Flexibility Thinner wires can offer more flexibility, which might be useful in applications that require bending or shaping without breaking. However, too much flexibility can lead to slippage or inadequate support for heavier loads.

3. Cost The price of baling wire often varies with the gauge. Thicker wires typically cost more, so choosing the correct thickness based on your needs can help manage operational costs.

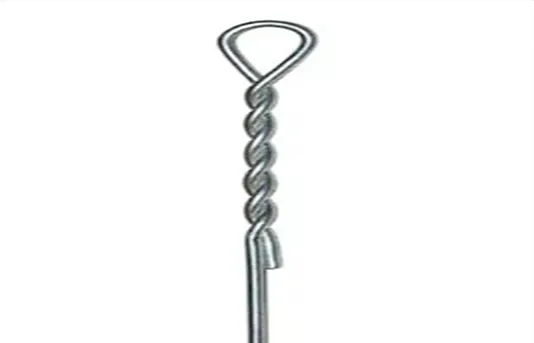

baling wire gauge

4. Application Specifics Different applications may require different gauges. For example, agricultural applications may need a thicker wire for hay bales, while lighter tasks, such as bundling newspapers, could be accomplished with a thinner wire.

Common Wire Gauges for Baling

When it comes to baling wire, there are a few common gauges that you might encounter

- 10 to 12 Gauge These thicker wires are often used in heavy-duty applications, such as securing large agricultural products or heavy manufacturing materials. Their robustness ensures that they can withstand significant pressure and weight.

- 14 to 16 Gauge These gauges are commonly used in moderate applications. They strike a balance between strength and flexibility, making them suitable for general bundling tasks.

- 18 to 20 Gauge Thinner wires in this range are used for lightweight jobs, such as bundling paper, cardboard, or small-scale agricultural products. While they are cost-effective, it’s essential to ensure that they can support the weight of the materials being bundled.

Conclusion

Understanding baling wire gauge is crucial for anyone involved in its use, be it in recycling, agriculture, or manufacturing. Choosing the right wire gauge can significantly impact the effectiveness of your operations, ensuring that materials are securely and efficiently bundled. Whether you require heavy-duty support for large bales or lightweight assistance for smaller items, there is a suitable baling wire gauge for your needs. Always consider the specific requirements of your application and consult with suppliers if you are unsure about which gauge would be best. Taking the time to select the appropriate baling wire will lead to better outcomes in your projects and operations, fostering efficiency and savings in the long run.

-

Reinforce Your Projects with Versatile Hexagonal Wire MeshNewsSep.12,2024

-

PVC WireNewsSep.12,2024

-

Maximize Your Closet Space with Clothes Hanger WireNewsSep.12,2024

-

Enhance Safety and Stability with Premium Rock Netting SolutionsNewsSep.12,2024

-

Bucket Handle WireNewsSep.12,2024

-

Baling Wire: Your Ultimate Solution for Securing and BundlingNewsSep.12,2024

-

What’s the Cost of Securing Your Property? Breaking Down Barbed Wire Fence PricesNewsAug.30,2024