-

Phone:

Phone: -

Email:

Email:

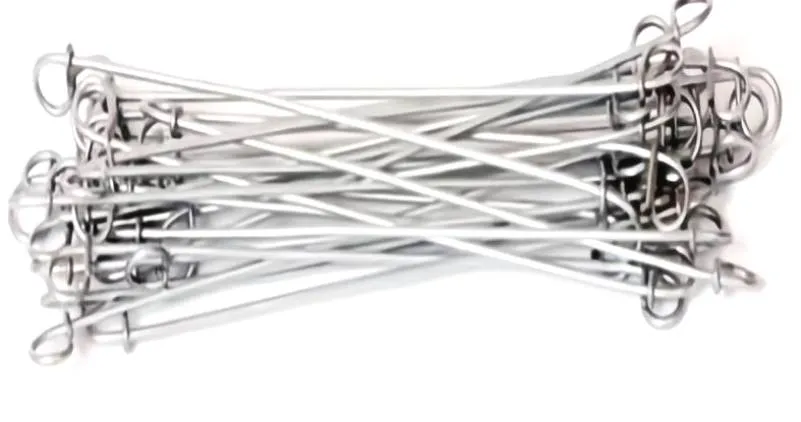

baling wire price

The Price of Baling Wire Understanding Market Trends and Factors

Baling wire, an essential component in various industrial and agricultural applications, plays a crucial role in securing and bundling materials. Commonly used in recycling, farming, and construction, its price is influenced by several factors, including raw material costs, market demand, and economic conditions. Understanding these dynamics is vital for businesses seeking to optimize costs and ensure efficient operations.

One of the primary determinants of baling wire prices is the cost of raw materials, particularly steel. Baling wire is primarily made from steel or other alloys, making its price closely tied to fluctuations in the global steel market. When steel prices rise due to increased production costs, tariffs, or supply chain disruptions, the cost of baling wire also tends to increase. Conversely, when steel prices decline, consumers can expect to see a drop in baling wire costs, which may lead to increased demand as businesses look to optimize their expenses.

Market demand is another significant factor affecting baling wire prices. Industries such as agriculture, recycling, and construction rely heavily on baling wire for bundling or securing materials. During peak seasons, such as the harvest season in agriculture or heightened construction activity, the demand for baling wire can spike, driving prices higher. Additionally, the growing emphasis on recycling and sustainable practices has led to an increase in the need for baling wire, as companies seek to bundle recyclable materials efficiently. This trend may continue to push prices upward, especially if supply cannot meet the increased demand.

baling wire price

Economic conditions also play a critical role in the pricing of baling wire. In times of economic expansion, construction projects tend to increase, bolstering demand for baling wire. Conversely, during economic downturns, construction slows, leading to a decrease in demand and a subsequent drop in baling wire prices. Furthermore, geopolitical factors, such as trade agreements and tariffs, can affect supply chains and impact prices. For instance, any trade restrictions on steel imports can lead to higher costs for baling wire manufacturers, which ultimately translates to higher prices for consumers.

In addition to these factors, technological advancements and innovations in wire manufacturing can influence prices. As producers optimize production processes or develop new materials that offer better durability or cost-effectiveness, the pricing landscape may change. Companies that invest in advanced manufacturing technology may be able to reduce their costs and offer more competitive prices to customers.

In summary, the price of baling wire is shaped by a confluence of factors including raw material costs, market demand, economic conditions, and technological innovations. For businesses relying on baling wire, staying informed about these trends is essential for making strategic purchasing decisions. Monitoring market changes not only aids in cost optimization but also helps businesses plan effectively for future needs in an ever-evolving marketplace.

-

Reinforce Your Projects with Versatile Hexagonal Wire MeshNewsSep.12,2024

-

PVC WireNewsSep.12,2024

-

Maximize Your Closet Space with Clothes Hanger WireNewsSep.12,2024

-

Enhance Safety and Stability with Premium Rock Netting SolutionsNewsSep.12,2024

-

Bucket Handle WireNewsSep.12,2024

-

Baling Wire: Your Ultimate Solution for Securing and BundlingNewsSep.12,2024

-

What’s the Cost of Securing Your Property? Breaking Down Barbed Wire Fence PricesNewsAug.30,2024