-

Phone:

Phone: -

Email:

Email:

Fluctuations in Baling Wire Prices and Market Trends Analysis

Understanding Baling Wire Prices and Their Impact on the Recycling Industry

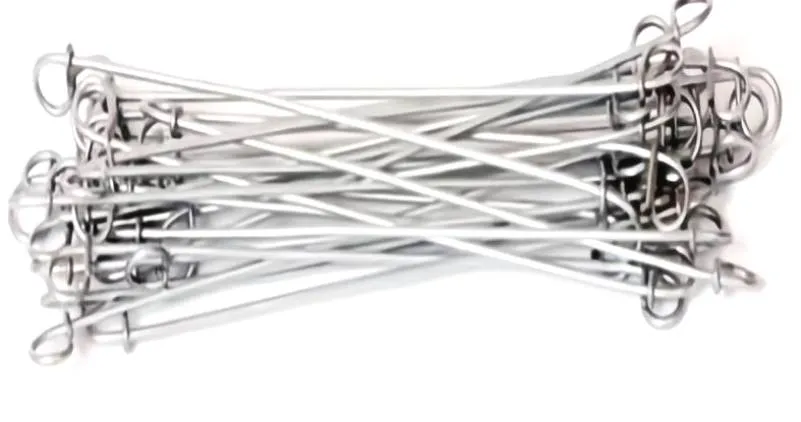

Baling wire is an essential material used in the recycling industry, primarily to bundle materials for storage and transportation. Its effectiveness in securing bales of materials like cardboard, plastics, and metals makes it a critical component in the process of recycling. As the demand for recycled materials continues to soar, understanding the factors influencing baling wire prices becomes increasingly important for recyclers and manufacturers alike.

The price of baling wire is influenced by various factors, including raw material costs, market demand, and global economic conditions. Baling wire is typically made of steel or aluminum, and fluctuations in the pricing of these base metals can significantly affect baling wire prices. For instance, when steel prices rise due to increased demand in construction or manufacturing sectors, baling wire prices are likely to follow suit. Conversely, if there is an oversupply of steel in the market, prices may drop, leading to more affordable baling wire.

Another significant factor is the overall demand for recycled materials. As environmental concerns prompt governments and industries to focus on sustainability, the demand for recycled products has surged. This heightened demand for recycling services often correlates with increased requirements for baling wire, which can drive prices higher. In addition, seasonal trends can also impact pricing; during certain times of the year, such as spring cleaning season, the volume of recyclable materials tends to increase, thereby boosting the need for baling wire.

baling wire price

Transportation costs also play a vital role in determining baling wire prices. Fluctuations in fuel prices can impact the overall cost of transporting baling wire to recycling facilities. Furthermore, logistics issues, such as shipping delays or shortages of delivery trucks, can create temporary surges in prices. Businesses must consider these factors when budgeting for baling wire as part of their operational costs.

Additionally, long-term contracts versus spot market purchases can also affect pricing strategies. Companies securing long-term contracts for baling wire often benefit from more stable prices, while those reliant on the spot market may face more volatility due to sudden price changes.

In conclusion, baling wire prices are subject to various influences, from raw material costs to market demand and transportation factors. For those in the recycling industry, staying informed about these dynamics is essential for making strategic purchasing decisions. As the push for sustainability grows, the interplay of these factors will likely continue to evolve, underscoring the importance of adaptability in managing operational costs associated with baling wire.

-

Reinforce Your Projects with Versatile Hexagonal Wire MeshNewsSep.12,2024

-

PVC WireNewsSep.12,2024

-

Maximize Your Closet Space with Clothes Hanger WireNewsSep.12,2024

-

Enhance Safety and Stability with Premium Rock Netting SolutionsNewsSep.12,2024

-

Bucket Handle WireNewsSep.12,2024

-

Baling Wire: Your Ultimate Solution for Securing and BundlingNewsSep.12,2024

-

What’s the Cost of Securing Your Property? Breaking Down Barbed Wire Fence PricesNewsAug.30,2024