-

Phone:

Phone: -

Email:

Email:

Coated Nichrome Wire for High-Temperature Applications and Electrical Resistance Solutions

The Versatility of Coated Nichrome Wire Applications and Benefits

Nichrome wire, an alloy of nickel and chromium, has long been recognized for its exceptional resistance to oxidation and high temperatures. But when it is coated, the potential applications and benefits of nichrome wire expand significantly, making it a sought-after material in various industries. This article delves into the properties of coated nichrome wire, its applications, and why it is preferred in numerous applications ranging from heating elements to resistors.

Properties of Coated Nichrome Wire

Coated nichrome wire retains the fundamental advantages of nichrome, which include high resistance to heat, electrical conductivity, and oxidation resistance. The coating, often made from materials such as silicone or polymer insulations, enhances these properties by providing additional protection against environmental factors such as moisture and chemicals. This makes coated nichrome wire extremely durable and able to withstand harsh conditions that would typically degrade uncoated metals.

The coating also allows for safer handling. The insulating material reduces the risk of electrical shorts or inadvertent contact with conductive surfaces, making it safer for users working with high-temperature applications. Moreover, the coating can come in various thicknesses and materials, adjusting to specific use cases that demand different thermal or chemical resistances.

Applications of Coated Nichrome Wire

1. Heating Elements One of the most common applications of coated nichrome wire is in heating elements for appliances like toasters, hair dryers, and industrial heating systems. The wire can be formed into coils and, when electrical current passes through, it generates heat. The coating helps prevent oxidation and enhances the durability of the heating element.

coated nichrome wire

2. Resistance Wires and Strips Coated nichrome wire is extensively used in the production of resistors, particularly for precision applications in automotive and aerospace industries. The resistance provided by nichrome wire is stable across a wide range of temperatures, making it ideal for applications where precise control of current is necessary.

3. 3D Printing In the burgeoning field of 3D printing, particularly for high-temperature and high-performance materials, coated nichrome wire is employed in heated print heads. Here, the resistance heating ensures that thermoplastics or other materials are melted consistently throughout the printing process.

4. Electronics The electronics industry leverages coated nichrome wire in various components. Its stable resistance properties make it suitable for power electronics and in applications where thermal stability is crucial. Additionally, its resistance to corrosion ensures that devices using this wire have a longer lifespan.

5. Automotive Applications Coated nichrome wire finds its place in engines, where it can be used in heating components or sensors. Given the extreme operating conditions of automotive environments, the coated wire’s durability and reliability offer significant advantages.

Conclusion

coated nichrome wire exemplifies the importance of materials science in modern technology. Its unique combination of thermal resistance, electrical conductivity, and protective coating makes it invaluable across various industries, from home appliances to advanced electronics. As technology continues to evolve, the applications for coated nichrome wire are likely to expand even further, underscoring its role in enhancing product performance and safety.

In summary, whether you are involved in the manufacturing of heating elements, automotive components, or precision electronics, coated nichrome wire is a material that not only meets but exceeds industry expectations, demonstrating the innovative potential of coated materials in engineering and design.

-

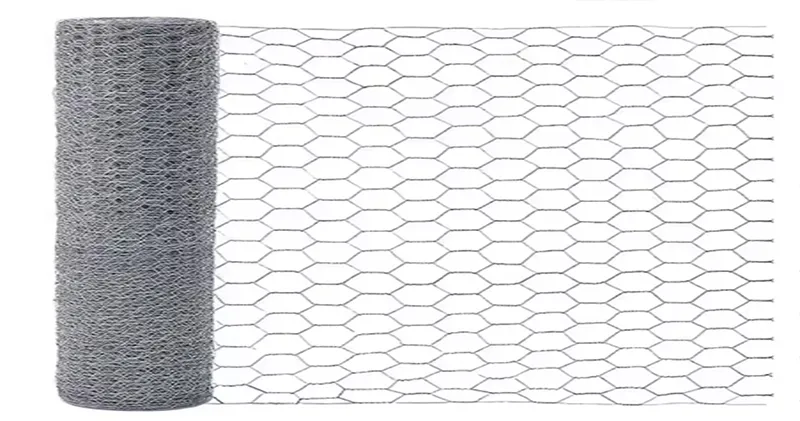

Reinforce Your Projects with Versatile Hexagonal Wire MeshNewsSep.12,2024

-

PVC WireNewsSep.12,2024

-

Maximize Your Closet Space with Clothes Hanger WireNewsSep.12,2024

-

Enhance Safety and Stability with Premium Rock Netting SolutionsNewsSep.12,2024

-

Bucket Handle WireNewsSep.12,2024

-

Baling Wire: Your Ultimate Solution for Securing and BundlingNewsSep.12,2024

-

What’s the Cost of Securing Your Property? Breaking Down Barbed Wire Fence PricesNewsAug.30,2024