-

Phone:

Phone: -

Email:

Email:

Durable Stainless Steel Baling Wire for Efficient Industrial Packaging and Recycling Applications

The Versatility and Strength of Stainless Steel Baling Wire

Stainless steel baling wire is an essential material in various industrial applications, particularly in the recycling and waste management sectors. With its durable and resilient properties, this type of wire is designed to provide strength and reliability for securing and bundling materials. This article explores the characteristics, benefits, and applications of stainless steel baling wire, highlighting its significance in modern industries.

Characteristics of Stainless Steel Baling Wire

Stainless steel baling wire is manufactured from high-quality stainless steel, making it resistant to corrosion and rust. This resistance is particularly important in environments where exposure to moisture and various chemicals is commonplace. The wire is typically available in different grades, including 304 and 316 stainless steel, each offering varying levels of corrosion resistance and durability.

Another notable feature is its tensile strength. Stainless steel baling wire is designed to withstand significant amounts of pressure and weight, making it ideal for bundling heavy materials. Its flexibility does not compromise its strength, allowing it to be bent and twisted without breaking. This property is crucial in applications where the wire needs to conform to different shapes and sizes of bundles.

Benefits of Using Stainless Steel Baling Wire

One of the primary advantages of stainless steel baling wire is its longevity. Unlike other materials, such as iron or plastic, stainless steel does not degrade or lose its properties over time, even when exposed to harsh environmental conditions. This means that investment in stainless steel baling wire pays off in the long run, as it minimizes the need for frequent replacements.

Additionally, stainless steel baling wire is environmentally friendly. As recycling becomes increasingly important in our society, using stainless steel wire facilitates the bundling and securing of recyclable materials. Moreover, stainless steel is fully recyclable, contributing to a more sustainable future by reducing waste.

stainless steel baling wire

Another benefit is its aesthetic appeal. The sleek, shiny surface of stainless steel provides a polished look, which can be advantageous in products where appearance matters. This is particularly relevant in applications involving consumer goods or where the bundled materials are visible.

Applications of Stainless Steel Baling Wire

Stainless steel baling wire is utilized across various industries. In the recycling sector, it is commonly used to bind cardboard, plastics, and metals, ensuring that materials remain secure during transportation and processing. This bundling is crucial for optimizing space and enhancing the efficiency of recycling operations.

In agriculture, stainless steel baling wire is employed for securing bales of hay or straw. The wire's strength ensures that bales remain intact and easily transportable, supporting farmers in effective storage and shipping of their products.

Manufacturers also use stainless steel baling wire in industrial applications, such as the automotive and construction sectors. It is often used for reinforcing components, where strength and durability are critical. Additionally, it is used in producing wire rope, essential for various lifting and securing applications.

Conclusion

In summary, stainless steel baling wire is a versatile and durable material that plays a crucial role in multiple industries. Its impressive strength, resistance to corrosion, and longevity make it an ideal choice for bundling and securing materials in recycling, agriculture, and manufacturing. As industries continue to prioritize efficiency and sustainability, the importance of stainless steel baling wire is likely to grow, solidifying its place as a fundamental resource in modern operations. The ongoing advancement in materials science ensures that stainless steel baling wire will continue to evolve, meeting the dynamic needs of various sectors while promoting a sustainable future.

-

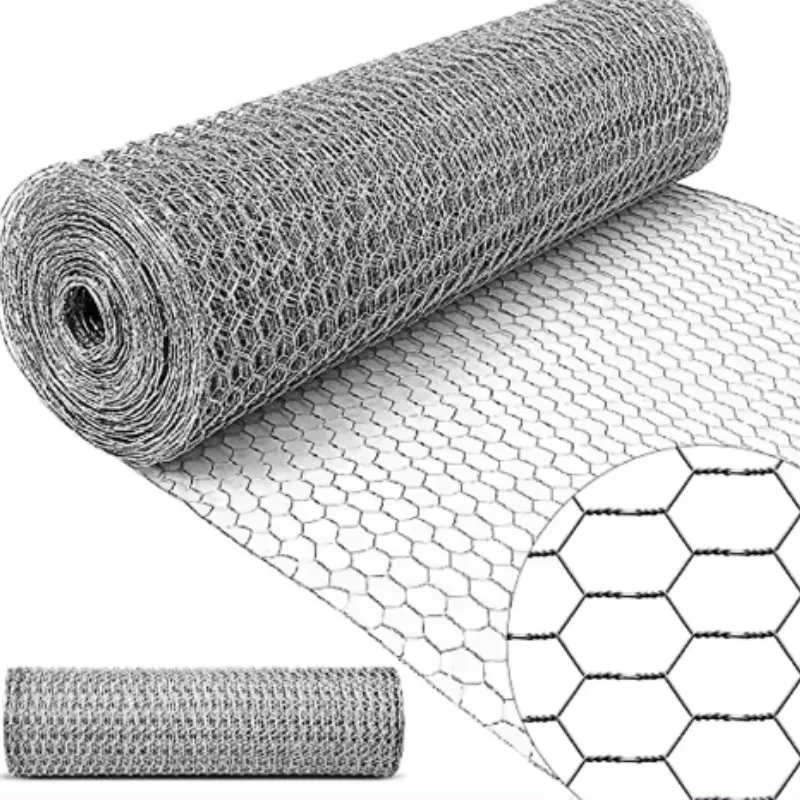

Reinforce Your Projects with Versatile Hexagonal Wire MeshNewsSep.12,2024

-

PVC WireNewsSep.12,2024

-

Maximize Your Closet Space with Clothes Hanger WireNewsSep.12,2024

-

Enhance Safety and Stability with Premium Rock Netting SolutionsNewsSep.12,2024

-

Bucket Handle WireNewsSep.12,2024

-

Baling Wire: Your Ultimate Solution for Securing and BundlingNewsSep.12,2024

-

What’s the Cost of Securing Your Property? Breaking Down Barbed Wire Fence PricesNewsAug.30,2024