-

Phone:

Phone: -

Email:

Email:

High-Performance PVC Automotive Wiring Solutions for Enhanced Durability and Safety

The Importance of PVC Automotive Wire in the Automotive Industry

In modern automotive manufacturing, electrical systems are crucial for the operation and functionality of vehicles. These systems rely heavily on wiring that provides reliable connectivity and ensures safety and efficiency. Among various materials, PVC (Polyvinyl Chloride) has emerged as a popular choice for automotive wiring due to its unique properties and advantages.

Durability and Resistance

One of the primary reasons PVC is widely used in automotive wire insulation is its exceptional durability. PVC exhibits a high level of resistance to abrasion, chemicals, and environmental factors such as moisture and extreme temperatures. This durability is vital in automotive applications, where wires are frequently exposed to harsh conditions. For example, wires in the engine compartment must endure heat from the engine and exposure to oils and fuels without degrading.

Electrical Insulation and Safety

Electrical insulation is another critical function of automotive wires, preventing short circuits and ensuring the safe operation of electrical systems. PVC offers excellent dielectric properties, which means it effectively insulates electrical currents, reducing the risk of electrical failures. Moreover, PVC automotive wire can be manufactured to meet stringent safety standards, minimizing the chances of electrical fires or failures that could lead to accidents.

Flexibility and Lightweight Design

pvc automotive wire

In the ever-evolving automotive industry, where efficiency and performance are paramount, the weight of materials can significantly affect overall vehicle performance. PVC automotive wires are lightweight, making them ideal for modern vehicles that strive for better fuel efficiency and reduced emissions. Additionally, PVC is highly flexible, enabling easy installation in various tight spaces within a vehicle. This flexibility also helps in managing the physical stress that occurs as vehicles operate and maneuver on the road.

Cost-Effectiveness

Another significant advantage of PVC automotive wire is its cost-effectiveness. Compared to other materials, PVC is relatively inexpensive to produce and process. This affordability allows automotive manufacturers to maintain competitive pricing while ensuring high-quality wiring systems. As the automotive industry moves toward more cost-effective and efficient production methods, PVC remains a favored choice for automotive wiring.

Environmental Considerations

While PVC has numerous benefits, there are environmental considerations regarding its production and disposal. The automotive industry is increasingly acknowledging the importance of sustainability and is exploring alternative materials and recycling methods to mitigate the environmental impact. Fortunately, many manufacturers are working on improving the recyclability of PVC and ensuring that it can be reused in various applications, contributing to a more sustainable automotive industry.

Conclusion

In conclusion, PVC automotive wire plays a crucial role in the automotive industry, offering durability, safety, flexibility, and cost-effectiveness. As vehicles become more advanced and the demand for efficient electrical systems increases, the significance of high-quality wiring cannot be overstated. While there are environmental challenges associated with PVC, ongoing efforts to improve sustainability are promising. Overall, the benefits of PVC automotive wire position it as a vital component in modern vehicle design and manufacturing, ensuring vehicles operate safely and efficiently in an increasingly complex automotive landscape.

-

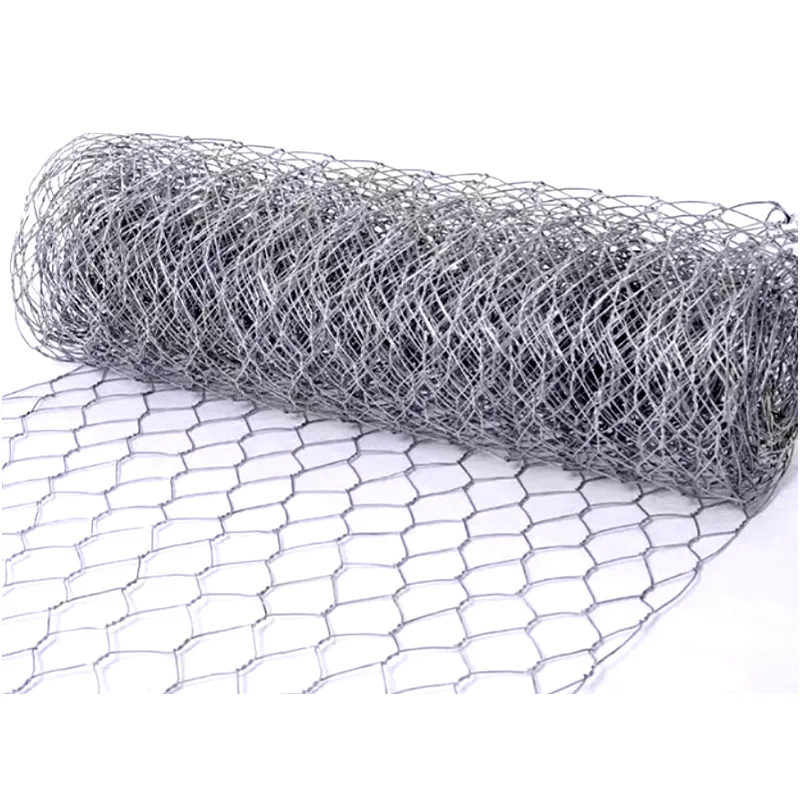

Reinforce Your Projects with Versatile Hexagonal Wire MeshNewsSep.12,2024

-

PVC WireNewsSep.12,2024

-

Maximize Your Closet Space with Clothes Hanger WireNewsSep.12,2024

-

Enhance Safety and Stability with Premium Rock Netting SolutionsNewsSep.12,2024

-

Bucket Handle WireNewsSep.12,2024

-

Baling Wire: Your Ultimate Solution for Securing and BundlingNewsSep.12,2024

-

What’s the Cost of Securing Your Property? Breaking Down Barbed Wire Fence PricesNewsAug.30,2024