-

Phone:

Phone: -

Email:

Email:

Durable PVC Stay Wire for Enhanced Support and Stability in Various Applications

Understanding PVC Stay Wire Applications and Benefits

PVC stay wire is an essential component in various industries, known for its durability and resistance to environmental factors. As the demand for reliable and long-lasting wire solutions increases, it is crucial to understand the nature of PVC stay wire, its applications, and the benefits it offers.

What is PVC Stay Wire?

PVC stay wire is a type of wire that is coated with polyvinyl chloride (PVC), a synthetic plastic polymer. This coating enhances the wire’s resistance to weathering, chemicals, and corrosion, making it suitable for outdoor use and in various industrial applications. The term stay wire usually refers to the wire used in supporting structures, such as telecommunications towers, utility poles, and other installations that require stability and tensioning.

Key Features of PVC Stay Wire

1. Durability The PVC coating provides excellent protection against harsh environmental factors, including ultraviolet (UV) rays, moisture, and chemical exposure. This durability extends the life of the wire and reduces the need for frequent replacements.

2. Flexibility PVC stay wire maintains certain flexibility, allowing it to accommodate slight movements and adjustments without breaking. This property is particularly beneficial in applications where there may be shifts in the structure or external forces acting on the wire.

3. Electrical Insulation The PVC coating serves as an insulator, reducing the risk of electrical conduction. This feature makes PVC stay wire an excellent choice for use in electrical and telecommunications applications, enhancing safety and performance.

4. Lightweight Compared to traditional steel wires, PVC stay wires are lighter, making them easier to handle and install. This lightweight nature contributes to lowering installation and transportation costs.

Applications of PVC Stay Wire

The versatility of PVC stay wire allows its use in numerous applications across different sectors

1. Telecommunications In telecommunication networks, PVC stay wires are used to support aerial cables and masts. Their resistance to corrosion and weathering is vital in maintaining the integrity of communication infrastructure, especially in challenging climates.

pvc stay wire

2. Agriculture Farmers use PVC stay wire for supporting crops, such as grapevines, and for fencing. The longevity and strength of the material help sustain the weight of climbing plants and protect farmland against intruders.

3. Construction In construction projects, PVC stay wire is often employed for bracing and support systems. It is used in scaffolding and reinforcement for various structures, ensuring stability and safety during the building process.

4. Utilities Utility companies utilize PVC stay wires to stabilize poles and aerial lines. The wire's strength and weather resistance are crucial for ensuring reliable service delivery, particularly in areas prone to severe weather conditions.

Benefits of Using PVC Stay Wire

Choosing PVC stay wire over traditional alternatives comes with several advantages

1. Cost-Effectiveness While the initial investment might be slightly higher than non-coated wires, the long lifespan and reduced maintenance costs of PVC stay wire make it a more economical option in the long run.

2. Environmental Resistance The resistance to moisture, UV rays, and chemicals means that PVC stay wires can withstand various environmental challenges without significant degradation.

3. Safety With its insulative properties, PVC stay wire minimizes electrical hazards, making it safer for use in a range of applications.

4. Easy Installation The lightweight nature of the wire simplifies the installation process, leading to reduced labor costs and quicker project completion.

Conclusion

Overall, PVC stay wire is an invaluable resource across various industries. Its unique properties of durability, flexibility, electrical insulation, and lightweight nature make it a preferred choice for many applications, from telecommunications to agriculture and construction. As industries continue to seek reliable materials, PVC stay wire stands out as a robust solution that meets both functional and economical needs. As technology and manufacturing techniques advance, we can expect further innovations in this field, enhancing the versatility and applications of PVC stay wire in the years to come.

-

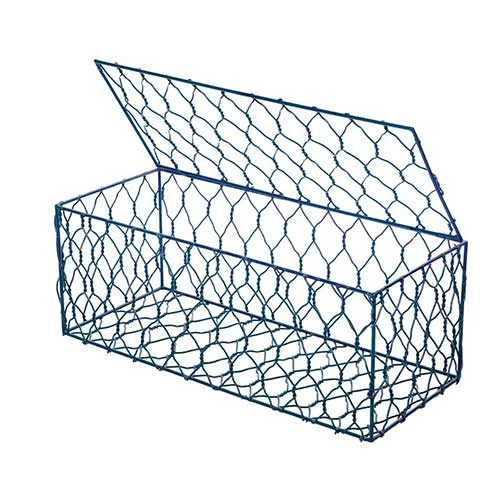

Reinforce Your Projects with Versatile Hexagonal Wire MeshNewsSep.12,2024

-

PVC WireNewsSep.12,2024

-

Maximize Your Closet Space with Clothes Hanger WireNewsSep.12,2024

-

Enhance Safety and Stability with Premium Rock Netting SolutionsNewsSep.12,2024

-

Bucket Handle WireNewsSep.12,2024

-

Baling Wire: Your Ultimate Solution for Securing and BundlingNewsSep.12,2024

-

What’s the Cost of Securing Your Property? Breaking Down Barbed Wire Fence PricesNewsAug.30,2024