-

Phone:

Phone: -

Email:

Email:

wire handles manufacturer

The Importance of Wire Handles in Manufacturing

In the world of manufacturing, functionality and efficiency are paramount. One often-overlooked component that plays a critical role in various industries is the wire handle. As a key element in the design of numerous products, wire handles serve not only as practical tools but also enhance the overall user experience. This article explores the significance of wire handles, their manufacturing process, and their applications across different sectors.

The Importance of Wire Handles in Manufacturing

The manufacturing process of wire handles involves several stages, starting from wire drawing, where raw materials are transformed into the appropriate gauge. This is followed by bending and forming, where machines shape the wire into handles of various configurations. Finally, the handles may undergo treatments such as galvanizing or powder coating to enhance their resistance to corrosion and wear, ensuring longevity in demanding environments.

wire handles manufacturer

One of the primary advantages of wire handles is their versatility. They can be used in a myriad of applications, from household items such as shopping baskets and storage containers to industrial uses like toolboxes and equipment carriers. In the food industry, wire handles are often employed in appliances and containers to facilitate easy transport while maintaining sanitation standards.

Additionally, wire handles contribute to ergonomic design. By providing a secure grip, they enable users to lift and transport items more comfortably, reducing the risk of strain or injury. This is especially important in industrial settings, where employees often handle heavy loads. Manufacturers focusing on the design and functionality of wire handles are not only meeting safety standards but are also promoting a culture of health and safety in the workplace.

As sustainability becomes a focal point for many manufacturers, wire handles present an eco-friendly option. They can be made from recyclable materials, and the longevity and durability of metal wire handles minimize waste. By investing in high-quality wire handles, businesses can reduce their carbon footprint while still delivering reliable and effective products.

In conclusion, wire handles are a vital component in manufacturing, offering versatility, durability, and ergonomic benefits across various industries. Their strategic use can enhance product functionality, improve user experience, and contribute to sustainable practices. As manufacturers continue to innovate and prioritize quality, wire handles will remain essential in the development of efficient and effective solutions for consumers and businesses alike.

-

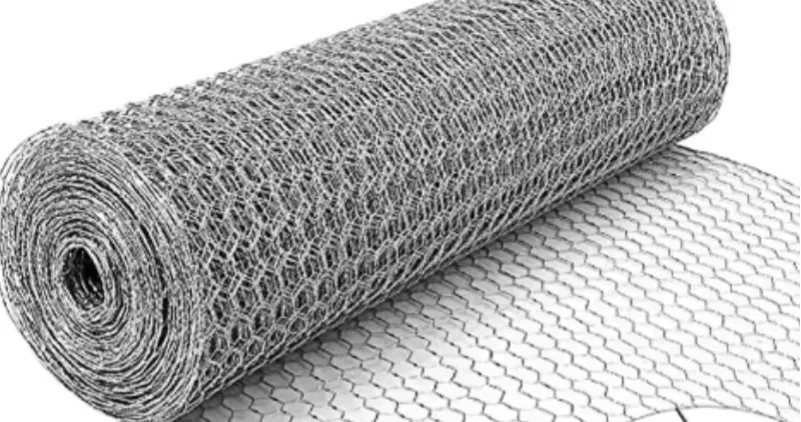

Reinforce Your Projects with Versatile Hexagonal Wire MeshNewsSep.12,2024

-

PVC WireNewsSep.12,2024

-

Maximize Your Closet Space with Clothes Hanger WireNewsSep.12,2024

-

Enhance Safety and Stability with Premium Rock Netting SolutionsNewsSep.12,2024

-

Bucket Handle WireNewsSep.12,2024

-

Baling Wire: Your Ultimate Solution for Securing and BundlingNewsSep.12,2024

-

What’s the Cost of Securing Your Property? Breaking Down Barbed Wire Fence PricesNewsAug.30,2024