-

Phone:

Phone: -

Email:

Email:

wire handles manufacturer

Wire Handles Manufacturer Crafting Innovation and Quality

In today's fast-paced manufacturing environment, the role of specialized producers like wire handles manufacturers has become increasingly critical. These companies supply essential components for a wide range of industries, including automotive, consumer goods, and construction. Wire handles are not just functional; they also enhance the usability and aesthetics of products. This article delves into the intricacies of wire handle manufacturing, the materials used, production techniques, and the future direction of this essential sector.

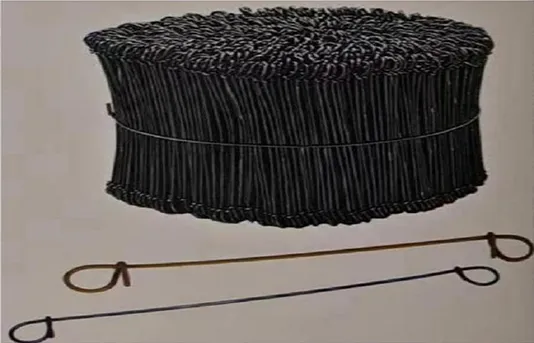

Wire handles are ubiquitous in everyday items—from bags to buckets and storage containers. They provide a practical means of transportation while contributing to the overall design of a product. The manufacturing process begins with selecting the right materials, which is crucial for the handle’s strength, durability, and appearance. Common materials include stainless steel, aluminum, and various types of plastic-coated wires. Each material has distinct properties; for instance, stainless steel offers high corrosion resistance, making it ideal for outdoor applications, while aluminum is lightweight and excellent for portable products.

Once the material is chosen, manufacturers employ various techniques to shape and design the wire handles. The most common methods include bending, welding, and coating. Bending is often done using specialized machinery that ensures precision in curvature and dimensions, which is vital for product compatibility and ergonomics. Welding, on the other hand, is used to join different wire pieces together, ensuring that the handle is sturdy enough to hold the weight of the product it is designed for. Coating processes, such as electroplating or powder coating, not only enhance the aesthetic appeal but also improve the handle's resistance to wear and environmental elements.

wire handles manufacturer

Quality control is a vital aspect of wire handle manufacturing. Reputable manufacturers adhere to stringent quality assurance protocols to ensure that every handle meets industry standards and customer expectations. This includes checking for defects, measuring strength, and testing for finish durability. Advanced technologies such as computer-aided design (CAD) and automated inspection systems have revolutionized the quality assurance processes, allowing for greater accuracy and efficiency.

With the growing emphasis on sustainability, wire handle manufacturers are also adapting their practices. This includes sourcing materials from recycled sources and implementing energy-efficient production techniques. The push for eco-friendly products is not only beneficial for the environment but also caters to the rising consumer demand for sustainable options. By adopting green practices, manufacturers can differentiate themselves in a competitive market, appealing particularly to environmentally conscious consumers.

The future of wire handle manufacturing is bright, driven by innovations in materials and production techniques. Advances in smart materials, which can be engineered to change properties in response to environmental stimuli, may open new avenues for product development. Additionally, the rise of automated manufacturing processes and Industry 4.0 principles promises to increase efficiency and reduce costs, ensuring that manufacturers can meet the evolving needs of their customers.

In conclusion, wire handles manufacturers play a vital role in the broader manufacturing landscape by providing essential components that enhance product functionality and appeal. As they continue to innovate and adapt to changing consumer expectations and environmental considerations, these manufacturers are poised to remain integral players in a dynamic industry. Their commitment to quality, sustainability, and technological advancement will undoubtedly shape the future of wire handle production and its applications in various sectors.

-

Reinforce Your Projects with Versatile Hexagonal Wire MeshNewsSep.12,2024

-

PVC WireNewsSep.12,2024

-

Maximize Your Closet Space with Clothes Hanger WireNewsSep.12,2024

-

Enhance Safety and Stability with Premium Rock Netting SolutionsNewsSep.12,2024

-

Bucket Handle WireNewsSep.12,2024

-

Baling Wire: Your Ultimate Solution for Securing and BundlingNewsSep.12,2024

-

What’s the Cost of Securing Your Property? Breaking Down Barbed Wire Fence PricesNewsAug.30,2024