-

Phone:

Phone: -

Email:

Email:

Cost Analysis of Baling Wire for Efficient Waste Management Solutions

Understanding the Cost of Baling Wire A Comprehensive Overview

Baling wire is an essential component in the recycling and waste management industries. It is used to bind various materials into manageable units, such as bales of cardboard, plastics, or metal scrap. While it may seem like a niche market, understanding the cost factors associated with baling wire is crucial for businesses relying on these materials. This article delves into the factors influencing baling wire costs, the different types available, and how to manage expenses effectively.

Factors Affecting the Cost of Baling Wire

1. Material Composition Baling wire is typically made from different types of materials, including steel, aluminum, and other alloys. The choice of material significantly impacts the price. For instance, steel baling wire tends to be cheaper than aluminum wire due to the abundance of raw materials and lower production costs. However, aluminum wire is often preferred for its lighter weight and resistance to corrosion, which may justify a higher price in certain applications.

2. Gauge and Strength The thickness of the wire, measured in gauge, also influences the cost. Thicker wires (lower gauge numbers) offer greater strength and durability, making them suitable for heavy-duty applications. Conversely, lighter gauges may be less expensive but may not withstand the same level of stress. Thus, businesses must balance cost and performance needs when selecting baling wire.

3. Market Demand and Supply Like any commodity, the cost of baling wire fluctuates based on supply and demand dynamics. During periods of high demand, such as increased recycling efforts or construction activities, prices may rise. Conversely, a surplus in wire production or a downturn in recycling efforts can lead to lower prices. Keeping abreast of market trends is essential for companies to make informed purchasing decisions.

4. Manufacturing Processes The method used to manufacture baling wire also affects costs. Some companies utilize advanced manufacturing techniques that may reduce production costs over time, while others may rely on traditional methods, leading to higher prices. Additionally, companies offering custom wire specifications may charge a premium for their services, reflecting the tailored nature of the product.

5. Shipping and Logistics The cost of transporting baling wire can significantly affect the overall price. Factors such as distance, shipping mode, and fuel prices all play a role in logistics costs. For businesses sourcing wire from remote locations or overseas, these expenses can add up, leading to higher final prices. To mitigate these costs, companies may consider purchasing wire locally whenever possible.

Types of Baling Wire

Baling wire comes in several varieties, including

baling wire cost

- Tie Wire Often used in agricultural settings, this lightweight wire is effective for securing bundles of hay or other crops. - Heavy-Duty Wire Designed for industrial applications, this wire can secure bulky materials like metal scraps or large cardboard bales, providing the strength necessary for demanding environments.

- Coated Wire Some baling wire is coated with materials like vinyl or plastic to enhance durability and rust resistance, making it suitable for outdoor or humid environments.

Cost Management Strategies

For businesses aiming to manage baling wire costs effectively, consider the following strategies

1. Bulk Purchasing Buying in bulk can often yield discounts. Businesses should evaluate their monthly needs and consider making larger purchases to reduce unit costs.

2. Supplier Relationships Establishing strong relationships with reliable suppliers can lead to favorable terms and pricing negotiations. Regular communication can also help keep businesses informed about potential price fluctuations.

3. Monitoring Trends Keeping an eye on market trends and raw material prices can help businesses time their purchases more strategically, allowing them to buy when prices are lower.

4. Investing in Quality While it might be tempting to opt for the cheapest wire available, investing in higher-quality baling wire can lead to cost savings in the long run. Higher durability means less frequent replacements and maintenance, reducing overall expenses.

Conclusion

Understanding the cost of baling wire is vital for businesses in the recycling and waste management sectors. By considering factors such as material composition, gauge, market dynamics, and logistics, companies can make informed decisions that align with their operational needs and budget constraints. With effective cost management strategies, businesses can ensure they maintain profitability while meeting their binding requirements efficiently.

-

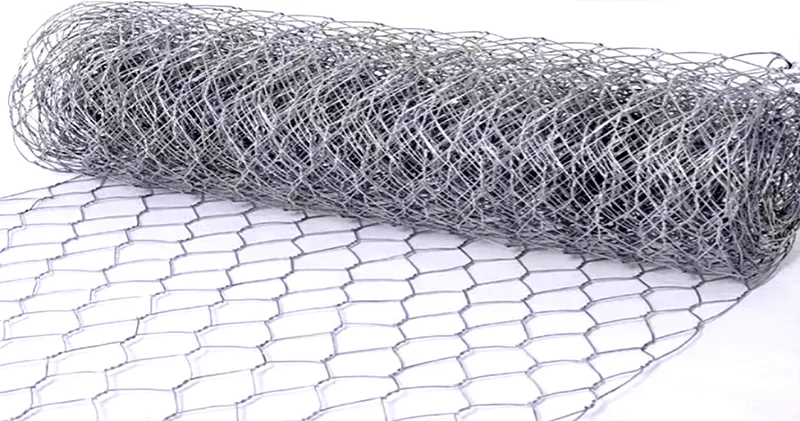

Reinforce Your Projects with Versatile Hexagonal Wire MeshNewsSep.12,2024

-

PVC WireNewsSep.12,2024

-

Maximize Your Closet Space with Clothes Hanger WireNewsSep.12,2024

-

Enhance Safety and Stability with Premium Rock Netting SolutionsNewsSep.12,2024

-

Bucket Handle WireNewsSep.12,2024

-

Baling Wire: Your Ultimate Solution for Securing and BundlingNewsSep.12,2024

-

What’s the Cost of Securing Your Property? Breaking Down Barbed Wire Fence PricesNewsAug.30,2024